Automotive Body Paint Line

The automotive body paint line is designed to repair minor damage to the paint of car bodies. This paint line incorporates a number of processes so that operators can refinish car bodies in the same line. Through a skid conveyor system which contains a transport skid that slides on ground rails, the car body enters the preparation area and moves laterally to go through all steps of panel beating, body filler applying, body filler drying, primer applying, primer drying, primer sanding, masking, top coat applying, top coat drying, polishing and assembling, significantly improving bodywork efficiency.

The in-line painting and drying booths were particularly designed to accommodate the paint line. The vertical lift doors are adopted at two sides of the each booth, allowing vehicles to easily pass through. Electric roll-up door and hydraulic vertical lift door are available to meet your preferences, which are driven by hydraulic lifting mechanism or electric motor respectively. The primer booth can be configured with strip curtains or electric roll-up doors.

Processes

- Dismantling

- Panel Beating

- Body Filler Applying

- Primer Applying

- Sanding

- Masking

- Top Paint Applying

- Drying

- Polishing

- Reassembly

Applications of Multi-Station Paint Line

- Dual-station paint line is suitable for quick repairing and painting tasks;

- Three-station paint line is suitable for common automotive repair shops;

- Four-station paint line is suitable for small-scale auto body paint centers;

- Five-station paint line is suitable for medium & large-scale auto body paint centers;

- VOC concentrator is recommended for air pollution control at paint booths;

Main Stations & Equipment of Paint Line

-

Skid Conveyor System

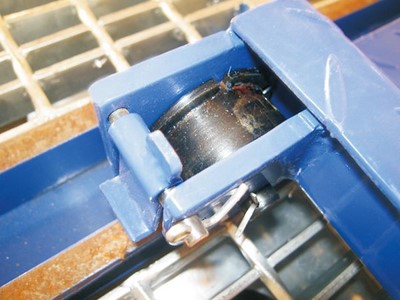

The transport skid is made from checkered plate through bending and forming process, featuring high durability without deformation. Bearings are mounted at all four wheels to minimize the sliding friction between the wheels and ground rail. Each wheel has independent braking and locking mechanism to guarantee the safety of operation. -

Infrared paint curing lamp

This paint curing lamp is adjustable in all directions to allow partial drying of fillers, primers and top coats, thus providing high flexibility and reducing costs.

Our technical team of seasoned professionals is large enough to handle your paint line projects associated with sanding, dedusting, spray painting, leveling and drying equipment. Our automotive body paint line is widely applicable to buses, cars, trucks, trains, motorcycles, specialty vehicles and heavy equipment. In addition to automotive body painting, this paint line is suitable for automotive interior painting and can also solve your painting needs across many industries such as machine tools, electric appliance, plastic parts and other items where spray painting is required.