Specifications

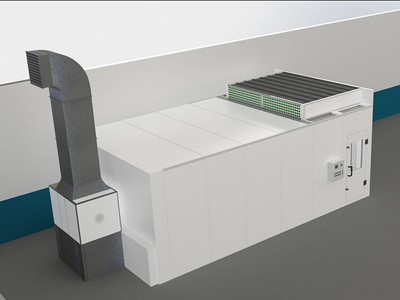

- Exterior dimensions: 7.5×4.0×3.2m

- Interior dimensions: 6.9×3.9×2.7m

- Access door width: 3.0m

- Access door height: 2.66m

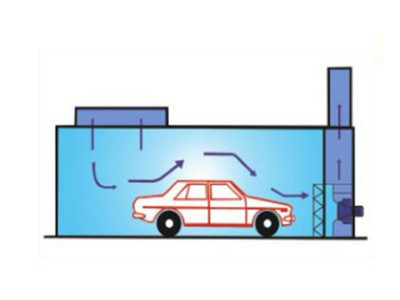

- Airflow: 18,000m 3 /h

- Air speed: 0.25-0.30 m/s

- Power: 7kw

- Applicable vehicle: sedan car

- Chinese standards or CE standards compliant (optional)

Standard Configurations

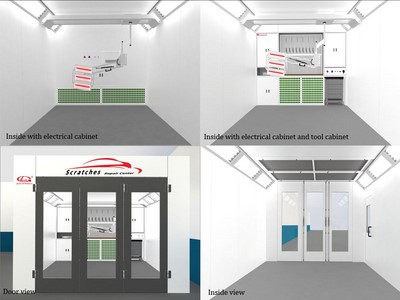

- Lighting system: upper lights are 8*4*18W LED light tubes, no lower lights;

- A tool cabinet and an electric control panel are integrated in to the rear wall of this paint booth. The tool cabinet is designed to add extra storage capacity to keep supplies and tools which are commonly used for sanding and painting. And the electric control panel contains emergency stop button, single-phase & three-phase sockets, compressed air quick release couplings, etc. This greatly increases paintwork efficiency while avoiding unnecessary entering and exiting the paint booth;

- Infrared paint curing lamp is optional;

Established in 1994, GZ Guangli has been focusing on manufacturing automotive paint booths, bus paint booths and automotive body paint lines for almost three decades. Among the current competition in the country, we are the oldest car spray booth manufacturing factory. Our manufacturing processes for paint booth production covers sheet metal processing, machining, punching, bending, welding, cutting, etc. GZ Guangli is well-known in the industry as it is at the forefront of the productivity and sales over the years in the domestic paint booth market. Our paint booths have been awarded the CE certificate, CCS (China Classification Society) certificate, ETL certificate, CU-TR certificate, SGS certificate, etc. We have provided products and service for a number of customers in automotive industry, such as GAC Toyota, Fiat, GAC Mitsubishi, Dongfeng Peugeot Citroen, Chery Automobile, JAC, Southeast Motor, BMW, Audi, FAW Toyota, FAW Mazda, FAW Hongqi, and more.

Inquiry